How to Customize T-Shirts: A Practical Guide for Wholesale Buyers and Decorators

By: ShirtsBargain Posted on: Jul 28, 2025How to Make Custom T-shirts Easily: Popular T-Shirt Customization Methods

- Screen Printing: This method remains the industry standard for bulk customization of t-shirts and promotional campaigns. With screen printing, ink is pushed through mesh screens or stencils onto the fabric. The result is a vibrant, durable print that appears slightly raised from the surface. The designs typically last a while, but the method is typically preferred for simple graphics with limited colors. Screen printing is very cost-effective and can produce sharp edges on designs really well.

- Dye Sublimation: Another popular t-shirt customization method, dye sublimation uses special inks that are subjected to heat and pressure to infuse into the fabric fibers of the t-shirt. The type of ink used here is one that permanently bonds with synthetic fibers. Sublimated t-shirts will have full-color, photo-like designs with smooth gradients. These designs are fade-resistant and neither crack nor peel.

- Direct to Garment (DTG) Printing: There is still a cult following for DTG, where designs are printed onto the fabric using specialized printers. DTG can produce detailed artworks on t-shirts, artworks with even complex color gradients. The method works exceptionally well on 100% cotton t-shirts and light-colored fabrics. The catch is that per-unit costs for DTG may run a little higher than screen printing. Read our blog to know more about DTG vs. screen printing.

- Direct to Film (DTF) Transfer: DTF is all the rage now, where decorators can create transfers on special films and apply them to garments using heat presses. It’s versatile and very fun to do. DTF works well on various fabric types, blends, and colors, including dark-colored t-shirts. The highlight is the durability and soft hand feel of the print. Like DTG, DTF also supports full-color designs. It can be either costly or cost-effective, depending on the size of the decoration run.

- Heat Transfer Vinyl (HTV): For HTV, the designs need to be cut from colored vinyl sheets and heat-pressed onto the t-shirts. They are exceptional for text-based designs and single-color ones. HTV does not require a lot of investment in equipment, and it delivers results almost immediately. The method is typically chosen for personalizing t-shirts.

- Embroidery: You don’t always have to use inks to customize t-shirts. The process of embroidering garments has a very long history, dating back not centuries but millennia. And it’s still synonymous with high-quality t-shirt designs. You can do it by hand, which takes a lot of time, or with digital embroidery machines. The machines come with a lot of handy features. Embroidery works well on 100% cotton t-shirts or denim t-shirts. They also work on blends with at least 50% cotton.

What You Need to Consider When Customizing T-Shirts

- Fabric Selection: Many of ShirtsBargain’s customers buy cotton-blend t-shirts in bulk for big decoration projects that employ multiple decoration methods. We recommend 100% cotton tees for DTG and embroidery. T-shirts made of synthetic fibers like 100% polyester are great for sublimation printing. Tri-blends are also gaining popularity in the market for the premium feel and compatibility with most decoration techniques.

- Garment Color and Weight: Light-colored t-shirts are typically chosen for decorations. But dark garments work well with specific methods like DTF or HTV. You should also consider the weight of the fabric, as it can affect not just the quality of the print but also its durability. Heavier fabrics, like t-shirts weighing over 6 ounces, obviously provide better stability in printing. Lightweight t-shirts are chosen by those who also prioritize garments that suit everyday wear.

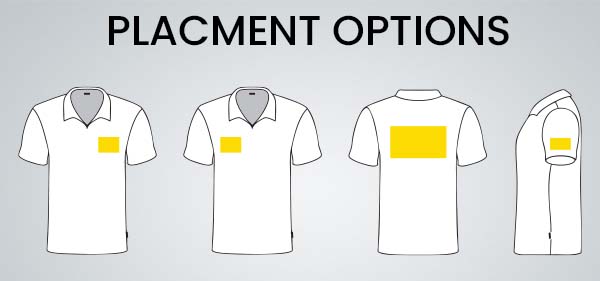

- Design Placement: Standard chest placement measures 4 inches down from the collar seam. Back designs typically sit 2 inches below the collar. Sleeve prints work best on the upper arm area. But your decision should also take the garment size variations into account. Designs may need to be scaled to match the t-shirt’s size.

- Washability: There are specific care guidelines for each printing method. Screen-printed garments can be washed at high temperatures, generally. But this doesn’t apply to DTG-printed t-shirts, which require cold water washes. When you are printing a lot of t-shirts, make sure to provide care instructions to your customers to maintain the quality of the prints.

How to Customize T-Shirts with ShirtsBargain

- Step 1: Click on the blue “Create Your Own” button on the ShirtsBargain website. Then click “Start Designing” to get started.

- Step 2: Click on “T-Shirts” in the filter and choose your preferred t-shirt type to see the styles in our blank t-shirt collection.

- Step 2: Navigate to the product page and click on the tab “With Embroidery.” Though the tab says Embroidery, we also offer other printing methods.

- Step 3: You will now see the product page for the style you chose. Simply select a color and click on the “Select Product and Start Design Now” button. This will take you to our FREE Design Creator tool.

- Step 4: Our Design Creator tool will now show options for you to add more products, add text/clip art, or upload your design in JPG, JPEG, PNG, and DST formats.

- Step 5: Choose from the front or the back area of the garment, add your design, and edit it in a lot of ways, including rotations and layering over other artworks. Then click either “Save Design” to save it to your account (if you are signed in) or click on “Continue to Add Sizes & Qty” to proceed.

- Step 6: Select the quantity and sizes, and click “Continue.”

- Step 7: Add your information and submit a quote to get back from our team. And leave the rest to us.

How to Start an Online Custom T-Shirt Business

- Research your target market and identify profitable niches. Analyze competitor pricing and offerings. Develop a business plan including startup costs, equipment needs, and marketing strategies.

- Choose your primary decoration method based on order volumes and design complexity.

- Source quality blank apparel from established suppliers like ShirtsBargain. Consistent inventory availability and competitive pricing impact your profit margins and customer satisfaction.

- Build an online presence through e-commerce platforms and social media marketing. Showcase design capabilities through portfolio galleries and customer testimonials. Offer design services alongside printing to increase average order values.

- Establish efficient workflows for order processing, production, and fulfillment. Invest in quality control measures to maintain product standards and customer loyalty.

Frequently Asked Questions

What do you need to make custom t-shirts by yourself?

You need blank t-shirts, a printing method (heat press, vinyl cutter, or printer), design software, and materials like heat transfer vinyl, transfer paper, or specialty inks, depending on your chosen technique.

What's the best way to make custom t-shirts?

DTG printing offers the best quality for detailed designs and small orders. Screen printing remains the most popular customization technique for bulk customization of t-shirts with simple graphics. Take the order volume, design complexity, and budget requirements into account before choosing a t-shirt decoration method.

What is the cheapest t-shirt printing technique?

Iron-on transfers using your home printer and special transfer paper offer the lowest initial cost. For professional results, screen printing can be quite cost-effective, especially for orders over 50 pieces.

How do I put a print on a t-shirt?

Apply heat transfer vinyl using a heat press at 305°F for 10-15 seconds. For DTG, pre-treat the shirt, print directly, and cure with heat. Screen printing requires creating screens, applying ink, and heat-curing the final print.

How profitable is a custom t-shirt business?

Custom t-shirt business profit margins typically range from 30% to 50%, with the market projected to grow to $10 billion by 2025. Find the right niche, offer the best prices, and streamline your operations continuously to accelerate your business towards success.

How long does custom t-shirt printing take?

DTG and heat transfer methods allow same-day completion for small orders. Screen printing typically requires 3-7 business days due to setup and curing time. Talk to our customer service representative to check if a rush order is possible.

Can you print on dark-colored t-shirts?

Yes, but methods can vary. DTF transfers and screen printing work well on dark fabrics, using specialty inks. DTG requires a white ink underbase for vibrant colors on dark shirts.